Explore the intelligence of the VISTAFLOW valve

Intelligent tramlining valve

10 years of success with more than 50,000 terminals sold worldwide! Today, the CCI innovation family is expanding with the arrival of the ISOBUS CCI 800 terminal and the new joystick with CCI A3 touchscreen.

Intelligent tramlining valve

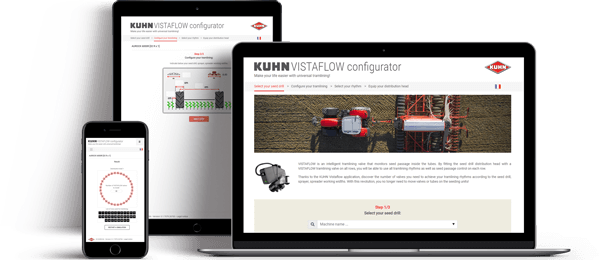

With the KUHN VISTAFLOW configurator, discover how many valves you need to achieve your tramlining rhythms according to your seed drill and treatment widths (sprayer and spreader). No more moving valves or tubes on the seeding units with this revolutionary system!

During spraying, speed, pressure and flow are closely linked to the type of nozzle used, forcing operators to limit their operating range. The AUTOSPRAY precision spray system eliminates all these constraints and makes operations easier: users select the droplet size and required application rate. They are then free to work accurately over a wide groundspeed range.

Fitted with Pulse Width Modulation technology (PWM), the AUTOSPRAY system’s smart nozzle holders dissociate spray pressure from nozzle speed.

The operator in the cab just needs to enter the dose and droplet size into the ISOBUS terminal. Highly accurate in spray quality, the AUTOSPRAY system is also fitted with the following functions:

In today’s farming context, it is a growing economic, environmental and societal challenge to reduce the consumption of plant protection products. Artificial intelligence is a breakthrough solution to reduce drastically chemical consumption. In partnership with CARBON BEE, KUHN is currently developing a sprayer that can locate and treat weeds, and only weeds.

Fitted with hyperspectral sensors on the boom, the sprayer constantly monitors the vegetation being treated. Artificial intelligence is used to analyse the images and recognise adventive species that need treating. The purpose is to open the required nozzle to spray only the targeted plant and thus strongly reduce the consumption of spraying products.

Initial figures show considerable savings in plant protection products, that can reach up to 80% just by reducing the treatment on the target plant. This technology opens the possibility of managing herbicide resistance, by using more targeted active substances.

Without I-SPRAY

With I-SPRAY

The OPTIDISC ELITE cutter bar is the result of more than 50 years of experience in the field of disc mowers. This practical solution combines unmatched cutting quality, high reliability and comfort of use. Developed in collaboration with farmers, the requirements of large farms and contractors are more than met: lifetime lubrication and perfect compatibility with high-powered tractors.

By fine-tuning the technical details of mowers, KUHN helps make the most of your forage to increase your profitability. The position of the discs and their spacing ensures a clean cut and promotes the forage flow to the swath. High-end components reinforce the core of the cutter bar. Forage quality and sward are preserved. Mow with peace of mind even in difficult conditions.

MyKUHN, the new on-line customer area

MyKUHN is your on-line customer area. Create your account today and discover how the exclusive services offered by MyKUHN will facilitate the management of your KUHN machine fleet.

188.9 hectares in 8 hours

KUHN has set the Raking World Record: 188.9 hectares in 8 hours, certified by the DLG (Deutsche-Landwirtschaft-Gesellschaft).

Step into the Raking World Record in Denmark. The 4 rotor gyrorake GA 15131 from KUHN’s range of hay & forage making machines set the record, coupled to a 6250R John Deere tractor.

More than 190 years of Excellence

Today, more than ever, we believe in the future of agriculture and our industry. Our 190 years of experience and the commitment of our staff, combined with the performance of our distribution networks that ensure proximity with customers, enable us to look to the future with passion and confidence.